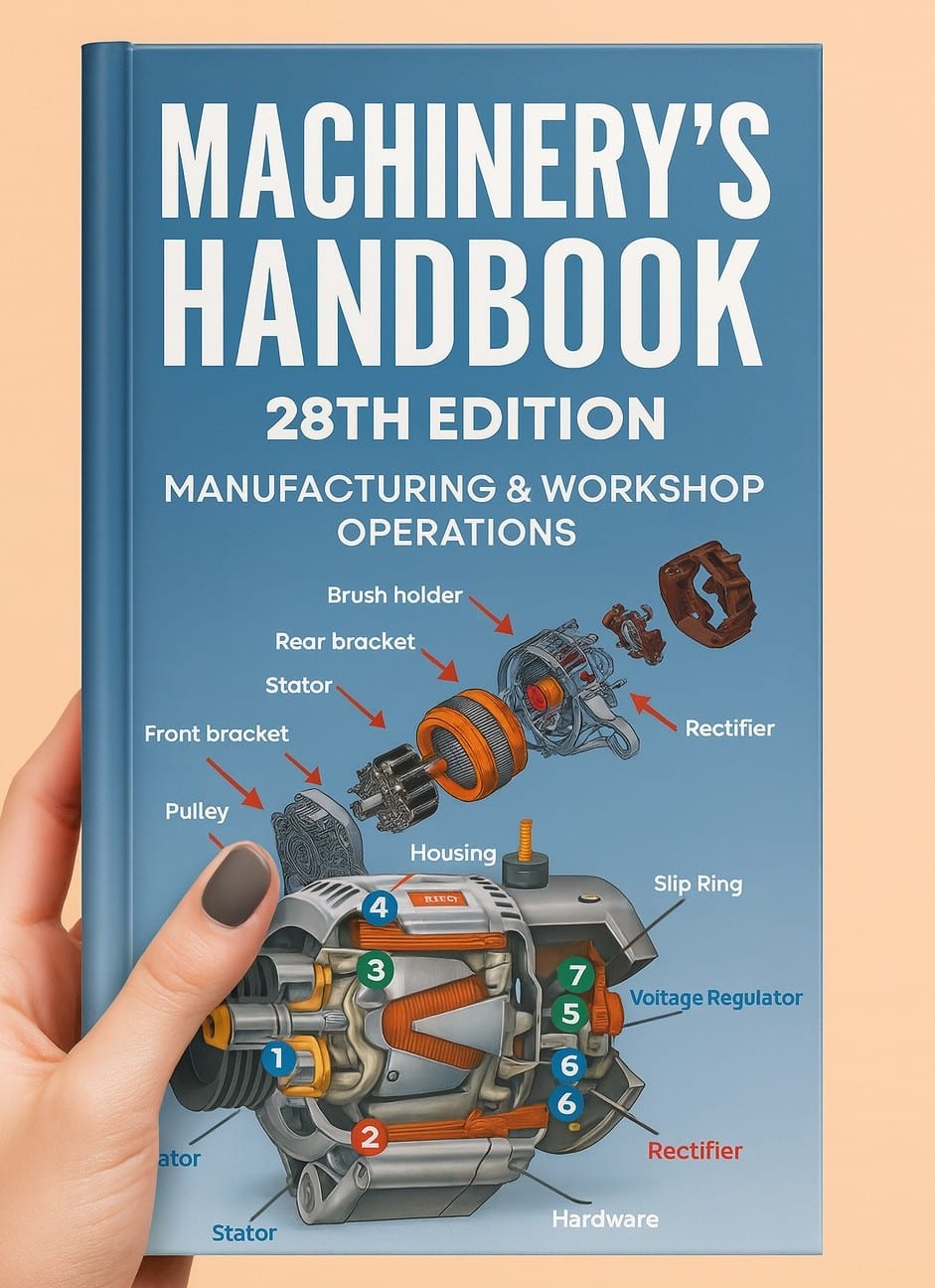

The Machinery’s Handbook 28th Edition Pdf For Free is one of the most sought-after resources for engineers, machinists, designers, and students across mechanical and industrial fields. Often referred to as the “Bible of Machine Shop Practice,” it serves as a trusted companion for professionals who need accurate data, charts, and guidelines on topics such as gears, threading, tolerances, welding, materials, fasteners, and manufacturing processes. With over a century of history, the handbook remains a cornerstone of reference literature for those working in precision engineering, mechanical design, and advanced manufacturing.

The 28th edition represents a refined and updated version, incorporating new standards, expanded tables, and modernized terminology. Accessing the Machinery’s Handbook 28th Edition Pdf For Free allows students and professionals to explore these resources conveniently, especially when physical copies may be costly or difficult to carry around.

Before reading further, watch this video to understand how exhaust smoke color helps diagnose engine problems.

A Brief History of Machinery’s Handbook

The first edition of Machinery’s Handbook was published in 1914 by Industrial Press. It was designed as a comprehensive reference for machinists, engineers, and designers working in the fast-growing industrial sectors of the early 20th century. Over the decades, the handbook has evolved to include not only traditional topics like drilling, milling, and threading but also advanced content in CNC programming, robotics, and additive manufacturing.

By the time of the 28th edition, the book had cemented its reputation as the gold standard in mechanical reference materials. Each new release integrates changes in ISO standards, ANSI codes, ASME guidelines, and ASTM specifications, ensuring that readers stay up to date with industry best practices.

What Makes the 28th Edition Special

The 28th edition stands out because it updates critical information relevant to modern manufacturing practices. Among the new additions are expanded sections on metric standards, surface roughness, screw thread tolerances, and updated GD&T (Geometric Dimensioning and Tolerancing) practices. These updates ensure that engineers can confidently design and produce components that meet international quality standards.

In addition, the handbook offers improved coverage of materials engineering, with updated mechanical properties for steels, alloys, plastics, and composites. This makes it invaluable not only to machinists but also to materials scientists and mechanical engineers who must select the right material for high-performance applications.

In-depth article on : 27th Edition Machinery’s Handbook Pdf For Free

The Role of Standards in Machinery’s Handbook

One of the greatest strengths of the Machinery’s Handbook lies in its extensive coverage of engineering standards. The 28th edition provides detailed references to ANSI, ISO, ASME, and ASTM standards, which guide everything from thread forms and fit classes to welding symbols and tolerance limits. These standards ensure that components designed in one part of the world will fit and function properly with those made elsewhere, maintaining global consistency in manufacturing.

For example, when designing a screw thread, an engineer can consult the handbook to confirm the proper pitch, thread angle, and tolerances according to ISO metric standards or Unified Thread Standards (UTS). This ability to reference authoritative data in one place makes the handbook indispensable for accurate engineering design.

Coverage of Manufacturing Processes

The Machinery’s Handbook 28th Edition Pdf For Free includes comprehensive information on manufacturing processes such as casting, forging, machining, welding, and additive manufacturing. Each process is explained with its advantages, limitations, and design considerations, making the handbook a valuable tool for both design engineers and shop-floor machinists.

For instance, the handbook provides detailed tables for cutting speeds and feeds for different tool materials and workpiece combinations. Whether using high-speed steel (HSS), carbide, or ceramic tools, machinists can find recommended cutting parameters to achieve efficiency while preserving tool life.

Practical Use in Machine Shop Work

In a typical machine shop, workers often rely on the Machinery’s Handbook to double-check calculations, look up formulas, or verify machining data. For example, when determining the proper clearance hole size for bolts, the handbook provides precise charts for both inch and metric standards. When programming a CNC machine, machinists can reference the section on speeds and feeds to optimize operations.

The portability of the Machinery’s Handbook 28th Edition Pdf For Free adds further convenience. Having the digital version on a laptop, tablet, or smartphone means machinists no longer need to flip through hundreds of pages to find the data they need.

Essential Topics Covered in the Handbook

Some of the most important technical areas covered include:

-

Mathematics and formulas: Algebra, geometry, and trigonometry applied to machining

-

Materials properties: Strength, hardness, elasticity, and thermal expansion

-

Threading data: Unified, metric, and pipe threads with tolerances

-

Tolerances and fits: Limits, allowances, and geometric tolerancing

-

Welding and fabrication: Symbols, practices, and joint design

-

Gear design: Spur, helical, bevel, and worm gearing calculations

-

Fasteners and bolts: Sizes, torque values, and strength ratings

-

Shop practices: Surface roughness, lubrication, and safety guidelines

Each of these sections provides practical data that saves time and prevents errors in both design and manufacturing.

Step-by-step tutorial for : Machinery’s Handbook 29th Edition Pdf For Free

The Value for Engineering Students

Students of mechanical engineering, manufacturing engineering, and industrial design find the handbook particularly useful. It bridges the gap between theoretical coursework and real-world application. For instance, a student studying gears can use the handbook to understand not only the formulas behind gear ratios but also the practical considerations of gear tooth design, backlash, and lubrication.

With the Machinery’s Handbook 28th Edition Pdf For Free, students can carry this massive resource digitally, making it a vital tool for exams, projects, and internships.

Applications in Mechanical Design

Mechanical designers use the handbook extensively when creating parts and assemblies. Whether working on shafts, bearings, couplings, or fasteners, designers need to ensure that every component meets safety and performance criteria. By referencing charts on clearances, surface finishes, and tolerances, designers reduce the risk of part failure and ensure compatibility with standard components.

Impact on Industry Professionals

For professionals, the Machinery’s Handbook serves as both a learning resource and a troubleshooting guide. Experienced machinists may not need to memorize formulas, but they rely on the handbook for conversion factors, material properties, and machining recommendations. Engineers working in multinational projects also depend on it to align designs with international standards, making it an essential tool in global manufacturing.

Why Accessing the PDF is Convenient

Carrying the physical edition of the handbook can be cumbersome since it often spans over 2,500 pages. The Machinery’s Handbook 28th Edition Pdf For Free offers the advantage of portability, quick searches, and digital bookmarking. Instead of thumbing through sections, users can quickly locate formulas or standards with a keyword search.

This convenience not only saves time but also ensures accuracy when working under tight deadlines on shop floors, in classrooms, or in design offices.