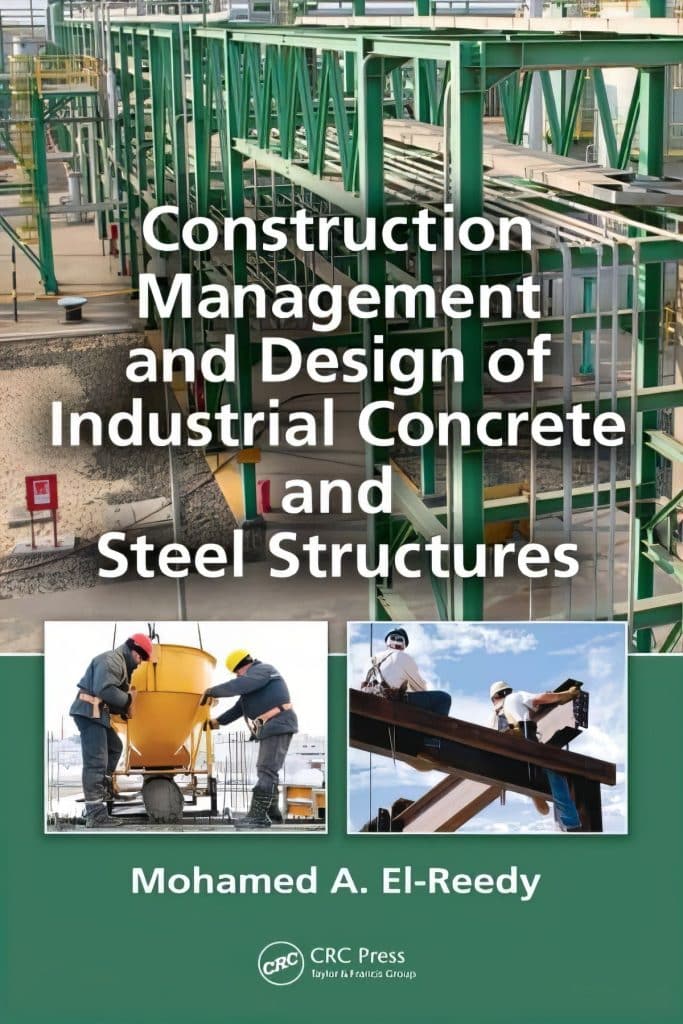

The study of construction management and design of industrial concrete and steel structures pdf for free provides invaluable knowledge to engineers, architects, and project managers. In the field of civil engineering, industrial projects rely heavily on the precise integration of structural design, load calculations, project scheduling, and material standards. Industrial facilities, such as factories, warehouses, and power plants, demand robust frameworks capable of withstanding heavy loads, vibrations, and dynamic stresses. This makes the role of concrete and steel structures central to ensuring safety, durability, and economic efficiency in construction projects. Access to free resources in this field empowers professionals and students to study critical topics without barriers.

Watch this simple video showing the main types of beams and where each is commonly used.

Importance of Construction Management in Industrial Projects

Construction management is the backbone of every industrial project. It covers areas like cost estimation, risk analysis, procurement planning, and resource allocation. Without efficient management practices, even the strongest steel structures or the most advanced concrete designs can fall short of project expectations. Managers must coordinate activities among engineers, architects, contractors, and suppliers to ensure deadlines and budgets are respected. In industrial projects, the stakes are especially high because delays can impact manufacturing timelines, supply chains, and long-term economic performance. Through structured management techniques, industrial construction maintains its competitive edge and sustainability.

Role of Concrete and Steel in Industrial Structures

When comparing concrete and steel, each material has unique advantages that make it suitable for industrial structures. Reinforced concrete (RC) is favored for its compressive strength and resistance to fire, making it ideal for foundations, floors, and retaining walls. Structural steel, on the other hand, offers high tensile strength, flexibility, and ease of prefabrication, which accelerates project timelines. Many modern industrial buildings combine both materials, with concrete serving as a stable base and steel forming the superstructure. This hybrid approach ensures stability while also reducing overall project costs.

Read the full guide on : Construction Management Of Steel Construction Pdf For Free

Codes and Standards in Structural Design

Industrial construction must comply with global and regional building codes and design standards. For concrete structures, standards such as ACI 318 (American Concrete Institute) and Eurocode 2 define structural requirements. For steel structures, references like AISC 360 (American Institute of Steel Construction) and Eurocode 3 are critical. These codes address load-bearing capacity, fatigue resistance, fire protection, and seismic performance. Engineers who study construction management and design of industrial concrete and steel structures gain familiarity with these codes, enabling them to deliver projects that are safe, efficient, and legally compliant.

Project Planning and Scheduling in Industrial Construction

Effective project planning ensures that all phases of industrial construction flow smoothly. The use of tools like Gantt charts and Critical Path Method (CPM) helps managers identify key tasks and potential bottlenecks. For example, when constructing a steel-framed warehouse, engineers must schedule the fabrication and transportation of prefabricated elements before on-site assembly begins. In contrast, with reinforced concrete, curing times play a major role in scheduling. Understanding the interplay of design and management practices is what makes industrial construction projects both practical and successful.

Design Considerations for Industrial Concrete Structures

Designing industrial concrete structures requires attention to strength, durability, and long-term maintenance. Engineers must account for live loads from equipment, dead loads from the structure itself, and environmental loads such as wind and seismic activity. In addition, exposure to chemicals or extreme temperatures can affect the integrity of concrete over time. For instance, a chemical plant floor may require special coatings or high-performance concrete mixes to withstand corrosion. Engineers studying these principles can apply them to a wide range of industrial settings.

Design Considerations for Industrial Steel Structures

The design of industrial steel structures revolves around optimizing strength while minimizing material usage. Lightweight yet strong, steel allows for long spans and open floor spaces, which are critical in factories and warehouses. However, steel must be protected from corrosion and fire. Design solutions often include protective coatings, fireproof cladding, and galvanization. Engineers must also account for vibration control in facilities with heavy machinery. Proper design ensures that the structure not only stands firm but also maintains performance under operational conditions.

In-depth article on : Construction Management Principles And Practice Pdf For Free

Integration of Concrete and Steel in Hybrid Designs

Many industrial projects rely on composite structures, where concrete and steel work together. For example, steel beams may support reinforced concrete slabs, creating a system that leverages both compressive and tensile strengths. Hybrid designs are especially useful in high-rise industrial facilities and energy plants. They offer flexibility for expansions and modifications, which are common in industries adapting to new technologies or production methods. This integration also improves energy efficiency and long-term cost savings.

Advanced Construction Technologies in Industrial Projects

The field of industrial construction has benefited greatly from modern technologies. Tools like Building Information Modeling (BIM) allow engineers and managers to create digital representations of projects, improving collaboration and reducing errors. Techniques such as prefabrication, modular construction, and 3D printing enhance efficiency and reduce waste. For example, prefabricated steel trusses can be manufactured off-site and quickly assembled on-site, shortening project timelines. These innovations are now central to the study of construction management and design of industrial concrete and steel structures.

Safety and Risk Management in Industrial Construction

Industrial construction is inherently complex and risky. Hazards include working at heights, handling heavy machinery, and exposure to chemicals. Safety management systems are essential to protecting workers and ensuring compliance with Occupational Safety and Health Administration (OSHA) standards. Engineers and managers must also plan for structural risks, such as fatigue failure in steel or cracking in concrete. By integrating safety into every stage of planning and execution, construction managers create a culture of risk awareness that minimizes accidents.

Cost Management and Resource Optimization

Industrial projects are capital-intensive, which makes cost management a critical discipline. Managers must balance quality and safety while keeping projects within budget. Strategies include bulk purchasing of steel sections, recycling of concrete aggregates, and energy-efficient construction techniques. The use of earned value management (EVM) helps monitor progress against budget forecasts, ensuring financial accountability. Successful industrial construction relies on this balance of economic efficiency and engineering excellence.

Step-by-step tutorial for : Handbook Of Construction Management Scope, Schedule, And Cost Control Pdf For Free

Sustainability in Industrial Concrete and Steel Structures

Modern projects increasingly emphasize sustainable construction practices. Industrial facilities consume significant amounts of energy and materials, making them targets for innovation. Engineers now explore green concrete mixes with supplementary materials like fly ash and slag, as well as recycled steel. Designing structures for adaptability and future use also reduces long-term environmental impacts. These practices align with global sustainability goals and position industrial construction as a driver of responsible development.

Educational and Professional Benefits of Free Resources

Access to construction management and design of industrial concrete and steel structures pdf for free benefits both students and professionals. For students, these resources serve as valuable study materials, offering examples, calculations, and case studies. For professionals, they act as references during project planning and design. Free resources also encourage knowledge sharing across regions, especially where access to expensive textbooks is limited. This democratization of information ensures that engineering knowledge is not confined to a select few.

Practical Applications of Industrial Structures

Industrial facilities are diverse, ranging from power plants and refineries to logistics warehouses and manufacturing hubs. Each requires a unique structural approach. For instance, a power plant may demand massive reinforced concrete foundations, while a warehouse benefits from lightweight steel framing for large, open spaces. The ability to apply design principles to various contexts is what makes industrial structural engineering both challenging and rewarding.

Future Trends in Industrial Construction

The future of industrial construction points toward greater use of automation, digitalization, and sustainable materials. Robotics and drones are already enhancing site safety and efficiency. Artificial intelligence is being integrated into project management software to predict delays and optimize schedules. At the same time, materials like ultra-high-performance concrete (UHPC) and advanced alloys in steel are redefining the limits of strength and durability. Students and professionals accessing free resources today are preparing themselves for this evolving industry.

3 comments

Ghai JOK

Those books are so helpful

Şakir

Pdf doküman

Akano Oluwabukola Ebenezer

Those ebooks are helpful, thanks.