The concept of setup planning for machining is central to manufacturing, where precise operations and process flow are essential for productivity. When engineers or machinists discuss setup planning, they are referring to the systematic process of determining how a workpiece should be positioned, oriented, and fixed on a machine tool to perform a series of machining operations efficiently. Having access to a Setup Planning For Machining pdf for free can help learners, students, and professionals quickly understand the fundamentals of fixture design, tool sequencing, and optimal resource use. By integrating this discipline into everyday practices, industries ensure reduced cycle time, better surface finish, and minimal material wastage.

Watch the video below to learn how the electric power steering (EPS) system works in modern vehicles.

Importance of Setup Planning in Manufacturing

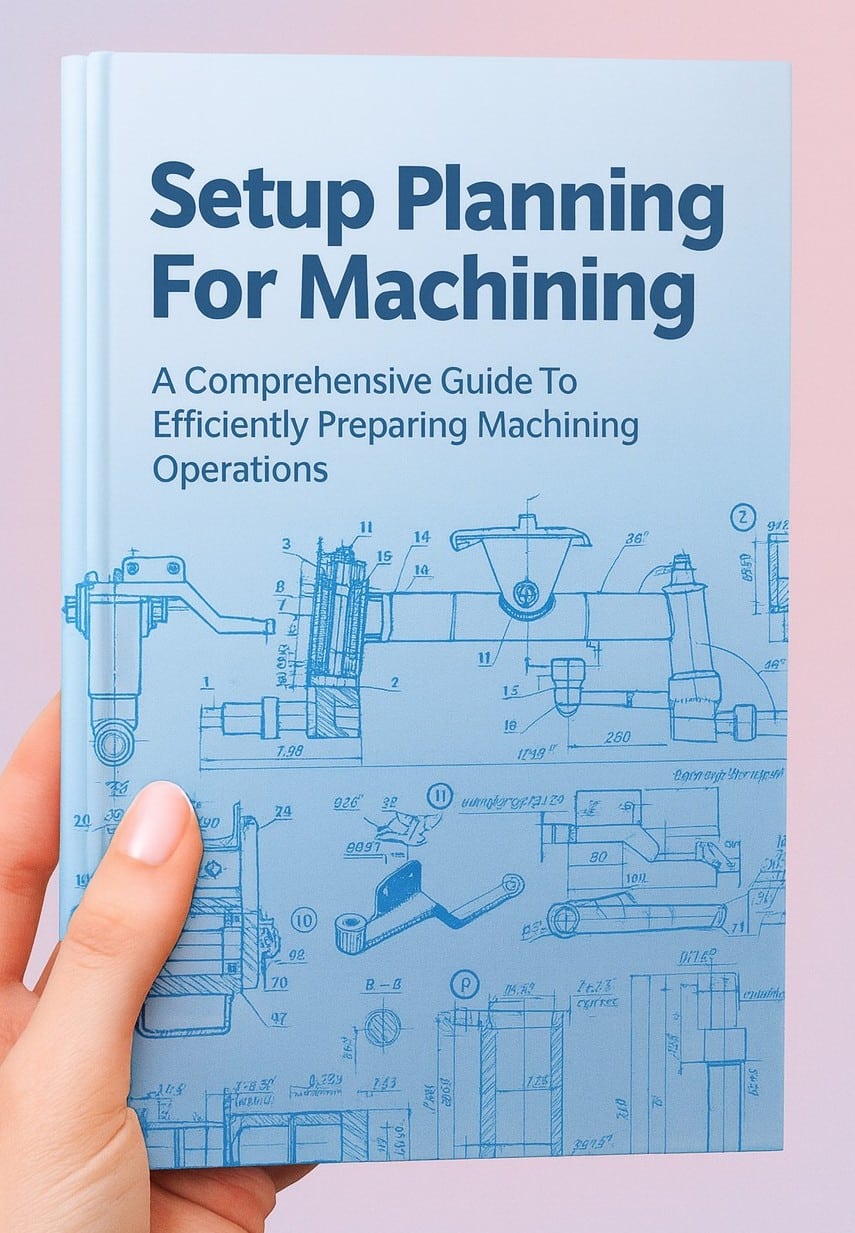

In modern manufacturing, setup planning serves as the bridge between computer-aided design (CAD) and computer-aided manufacturing (CAM). Without an effective setup plan, even advanced CNC machines cannot produce components accurately. For instance, if a hole pattern on an engine block is not aligned properly with the datum reference frame, subsequent drilling and milling operations may result in costly scrap. A structured setup plan provides the machinist with clear instructions on reference points, clamping methods, and the exact sequence of machining operations. This ensures consistency and repeatability, two pillars of mass production.

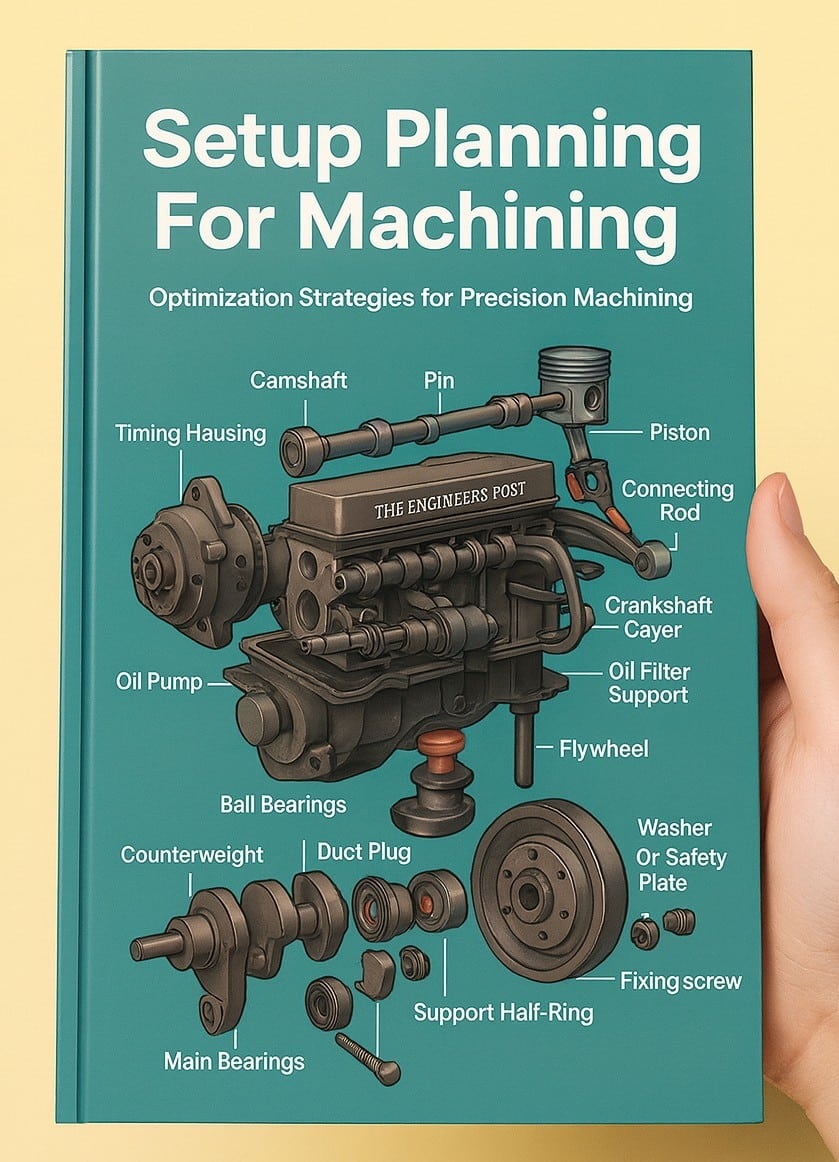

Role of Fixtures and Jigs

A significant aspect of setup planning revolves around the use of fixtures and jigs. Fixtures hold the workpiece securely, while jigs guide the cutting tools during machining. For example, in milling operations, a vice or custom fixture ensures that the workpiece does not shift under cutting forces. The choice of fixture is determined by part geometry, material, and the machining process involved. A comprehensive Setup Planning For Machining pdf for free often includes diagrams of fixture setups, highlighting how modular fixtures reduce lead time compared to traditional dedicated fixtures. Proper fixture design not only saves time but also improves accuracy in mass production environments.

Sequence of Operations in Setup Planning

The sequence of machining operations is another critical element. A well-prepared setup plan considers which surfaces should be machined first to create stable reference planes. For example, in a prismatic component, the largest flat surface may be machined first to act as the datum for subsequent drilling or pocket milling. By following this approach, errors due to uneven clamping or poor reference surfaces are avoided. Setup planning also evaluates tool changes, spindle speeds, and feed rates to reduce downtime. When students download a Setup Planning For Machining pdf for free, they gain insight into operation sequencing charts that demonstrate the relationship between each machining step.

Check out our guide : Automatic Transmission Mechanical And Hydraulic Systems Pdf For Free

Integration with CAD/CAM Systems

With the advancement of CAD/CAM integration, setup planning has become more streamlined. Engineers can simulate machining processes virtually before actual production. This not only identifies potential errors but also optimizes tool paths for efficiency. For example, software such as Mastercam or NX allows users to virtually test fixture setups and tool sequences. Access to a Setup Planning For Machining pdf for free can serve as a supplementary resource to these simulations, offering theoretical background alongside digital practice. Through this synergy, industries achieve faster prototyping and reduced product development cycles.

Tool Selection in Setup Planning

Tool selection plays a fundamental role in determining machining efficiency. The setup plan outlines which tools are required, their dimensions, and how they will be applied. Using the wrong cutting tool or improper tool path can lead to excessive tool wear, vibrations, and poor dimensional accuracy. A good setup planning guide emphasizes the use of indexable cutters, carbide inserts, and coolant strategies to maintain productivity. The availability of a Setup Planning For Machining pdf for free ensures that machinists can learn about tool libraries and standardization practices, which minimize inventory issues and ensure consistent performance across multiple jobs.

Datum Reference Frames and Alignment

The concept of datum reference frames is vital in machining. A datum serves as the origin point for all measurements and machining operations. In setup planning, datums must be chosen carefully to align with the design intent of the part. For example, a cylindrical shaft may use its centerline as the primary datum, while the flat end face serves as the secondary datum. This prevents misalignment during turning or grinding operations. Many Setup Planning For Machining pdf for free resources highlight practical case studies where improper datum selection led to misaligned features and rejected components.

Reducing Setup Time in Machining

Reducing setup time directly improves manufacturing efficiency. Techniques such as group technology (GT) and cellular manufacturing classify parts with similar features into families, allowing standardized fixtures and processes to be reused. Quick-change tooling systems and modular fixtures also cut down on time spent reorienting parts. For example, in aerospace industries where complex geometries are common, reducing setup time by even a few minutes can translate into significant cost savings. A reliable Setup Planning For Machining pdf for free provides tips on these strategies, empowering machinists to handle multiple jobs with ease.

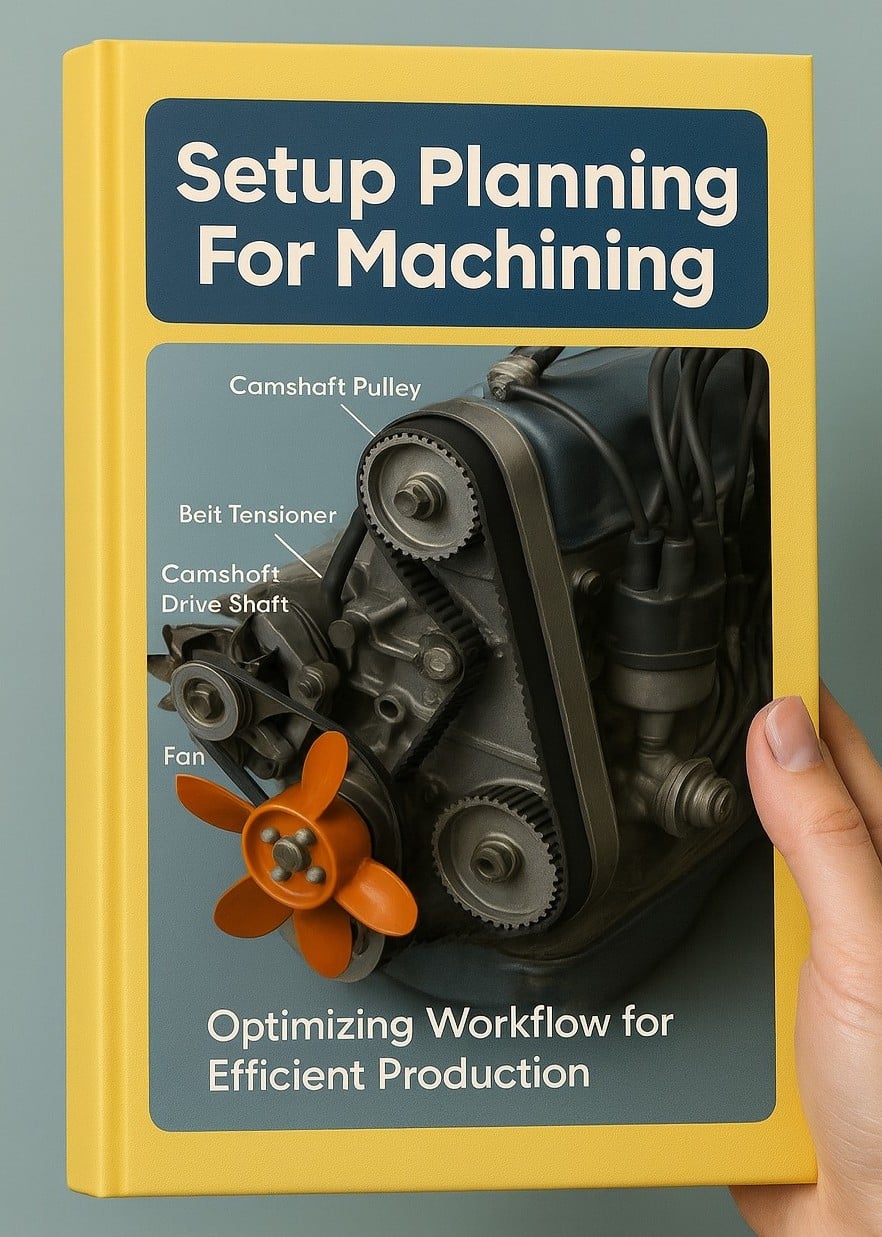

CNC Machining and Multi-Axis Setup Planning

In CNC machining, setup planning takes on additional complexity when multi-axis machines are involved. For example, a 5-axis CNC machine can access multiple surfaces in one setup, reducing the need for frequent repositioning. However, this requires careful planning of tool paths and collision checks. Engineers use simulation software to verify that rotary tables and tilting heads won’t cause tool interference. Having a Setup Planning For Machining pdf for free provides learners with step-by-step instructions on how to develop multi-axis machining strategies, balancing machine capability with part complexity.

Check All Books About This Field : Mechanical Engineering Books

Tolerances and Surface Finish Considerations

Setup planning is not just about positioning the workpiece; it also ensures that tolerances and surface finishes meet design requirements. For example, a bore with a tight tolerance of ±0.01 mm requires precision reaming or honing after rough machining. Surface finish, measured in Ra (roughness average), must also be controlled based on function. A sealing surface in an automotive engine requires a finer finish than a structural component. Detailed examples in a Setup Planning For Machining pdf for free explain how to sequence roughing and finishing operations to achieve the required balance between speed and accuracy.

Case Study: Automotive Component Setup Planning

Consider the example of machining a cylinder head in the automotive industry. The setup plan begins with machining the flat base to establish a datum surface. Next, the holes for cylinder head bolts are drilled using a fixture that ensures alignment with the engine block. The final stages involve finishing the combustion chamber surfaces with high precision to ensure sealing with the piston. This demonstrates how each step in the setup plan directly impacts functionality and reliability. Accessing a Setup Planning For Machining pdf for free allows students to explore such case studies and understand real-world applications.

Safety and Ergonomics in Setup Planning

Safety is a vital aspect of setup planning. Incorrect clamping or poor fixture design can cause the workpiece to shift or even eject during high-speed machining, posing risks to operators. Ergonomics also matter, as machinists must be able to load and unload parts efficiently. For example, in heavy industries, fixtures with hydraulic clamping reduce operator fatigue compared to manual clamping. Many Setup Planning For Machining pdf for free resources stress the importance of balancing productivity with workplace safety, ensuring a sustainable manufacturing environment.

Global Standards in Setup Planning

The field of setup planning also aligns with international standards such as ISO 9001 for quality management and ASME Y14.5 for geometric dimensioning and tolerancing (GD&T). These standards provide guidelines for datum selection, tolerancing, and quality control. For example, GD&T symbols help machinists interpret complex design drawings and align machining setups accordingly. A Setup Planning For Machining pdf for free often incorporates these standards, offering a universal language that ensures consistency across global supply chains.

Educational Value of Setup Planning Guides

For students and professionals in mechanical engineering and manufacturing disciplines, a Setup Planning For Machining pdf for free is a valuable resource. It bridges the gap between theory and practice, offering step-by-step examples, diagrams, and case studies. Universities often include setup planning modules in their courses, emphasizing its role in product design and process planning. By studying these materials, learners develop critical skills that prepare them for careers in precision engineering, CNC programming, and industrial automation.

2 comments

Bongani Wongama

I want to know everything about Mechanical Engineering

Juan III Martinez

I Want to Know Everything on Engine